- Min Order: 1set

- Supply Quantity: 100/month

- Loading Port: qingdao

- Description: This tapioca chips frying machine can be used in the production of various chips such as banana chips, cassava chips, yam, potato chips, etc.

Sale Continuous Tapioca Chips Making Machine For Frying

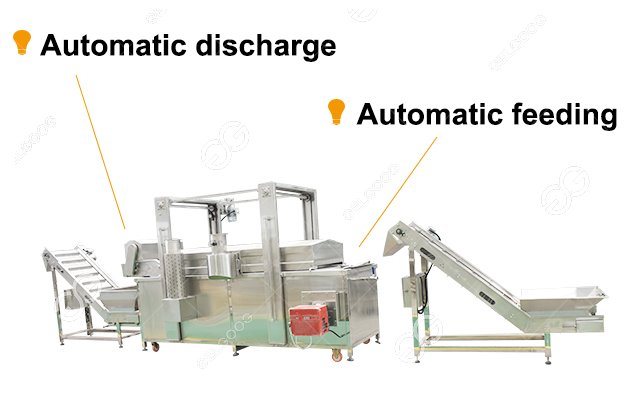

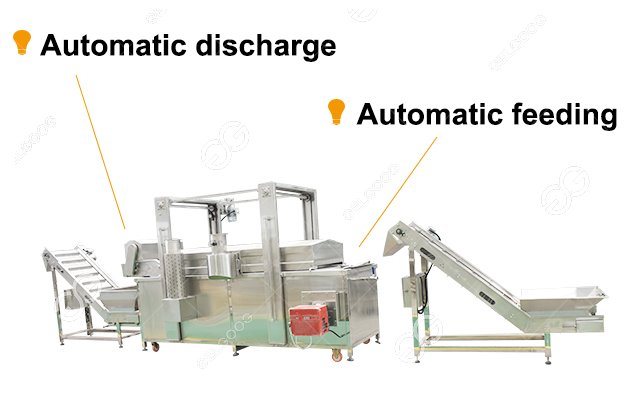

This electric heating tapioca chips frying machine mainly adopts a double-layer mesh belt design structure. Equipped with an automatic temperature control system inside, it can ensure that the oil temperature is not fluctuated during the frying process. The most important thing is that this stainless steel tapioca chips making machine can continuously fry a variety of crispy foods (french fries, cassava chips, sweet potatoes), reducing manpower and reducing costs.

Advantages Of Tapioca Chips Making Machine

Details Of Tapioca Chips Frying Machine

1. Double mesh belt

The mesh belt is wavy and has baffles, which can drive the uninterrupted transportation of food during the feeding and discharging process. In the frying process, it can prevent floating and make it evenly fried.

2. PLC control panel

It is convenient to control the operation of the whole tapioca chips frying equipment, which is used to adjust the temperature, the speed of the mesh belt and so on.

3. Filter

The residue produced in the frying process is coarsely filtered.

4. Automatic lifting device

Used to lift the upper cover and mesh belt of the tapioca chips making machine for easy cleaning.

Maintenance Method Of Tapioca Chips Frying Machine

1. Packaging

The tapioca chips frying machine will be covered with a film before transportation, and then placed in a wooden box to prevent it from breaking during transportation. After arriving at the destination port, it is convenient for customers to unload.

2. Shipment

We choose to ship directly in our own factory and send the machine to the customer in the shortest time. Update shipping information in time during transportation.

Advantages Of Tapioca Chips Making Machine

- The temperature control is more accurate, and the food with different temperature requirements can be fried.

- High thermal efficiency.

- High working efficiency, able to realize continuous operation.

- It can meet different output requirements, the output is between 150-1000kg/h.

- Separate and advance the product through the mesh belt of the frying machine, which can prevent agglomeration during the frying process.

- The uninterrupted residue filter system ensures that the frying oil is clean.

- Save frying oil, high oil turnover rate.

- The feeding and discharging can be completed automatically, saving manpower.

Details Of Tapioca Chips Frying Machine

1. Double mesh belt

The mesh belt is wavy and has baffles, which can drive the uninterrupted transportation of food during the feeding and discharging process. In the frying process, it can prevent floating and make it evenly fried.

2. PLC control panel

It is convenient to control the operation of the whole tapioca chips frying equipment, which is used to adjust the temperature, the speed of the mesh belt and so on.

3. Filter

The residue produced in the frying process is coarsely filtered.

4. Automatic lifting device

Used to lift the upper cover and mesh belt of the tapioca chips making machine for easy cleaning.

Maintenance Method Of Tapioca Chips Frying Machine

- Before using the fryer machine, add oil to the tapioca chips making machine to prevent the heating tube from burning out.

- After the frying machine is used for a period of time, the oil residue on the surface should be cleaned regularly to prevent fire.

- Regularly check the performance and sensitivity of each part of the frying machine.

- After the fryer machine is used, the frying oil needs to be cooled and discharged before cleaning. You can sprinkle edible alkali powder into boiling water for boiling cleaning.

1. Packaging

The tapioca chips frying machine will be covered with a film before transportation, and then placed in a wooden box to prevent it from breaking during transportation. After arriving at the destination port, it is convenient for customers to unload.

2. Shipment

We choose to ship directly in our own factory and send the machine to the customer in the shortest time. Update shipping information in time during transportation.

| Model |

Belt width (mm) |

oil pump power (kw) |

lifting power (kw) |

heating power |

Dimension (mm) |

| GGLZG3500A | 800 | 1.5 | 0.55 | 20Wkcal | 3700*1900*2400 |

| GGLZG5000A | 800 | 1.5 | 0.55*2 | 30Wkcal | 5200*1900*2400 |

| GGLZG6500A | 800 | 1.5 | 0.75*2 | 20Wkcal*2 | 6700*1900*2400 |

| GGLZG8000A | 800 | 2.2 | 0.75*2 | 30Wkcal*2 | 8200*1900*2400 |

| GGLZE3500A | 800 | 1.5 | 0.55 | 90KW | 3700*1600*2200 |

| GGLZE5000A | 800 | 1.5 | 0.55*2 | 120kw | 5200*1600*2200 |

| GGLZE6500A | 800 | 1.5 | 0.75*2 | 190kw | 6700*1600*2200 |

| GGLZE8000A | 800 | 2.2 | 0.75*2 | 255kw | 8200*1600*2200 |