- Min Order: 1set

- Supply Quantity: 100/month

- Loading Port: qingdao

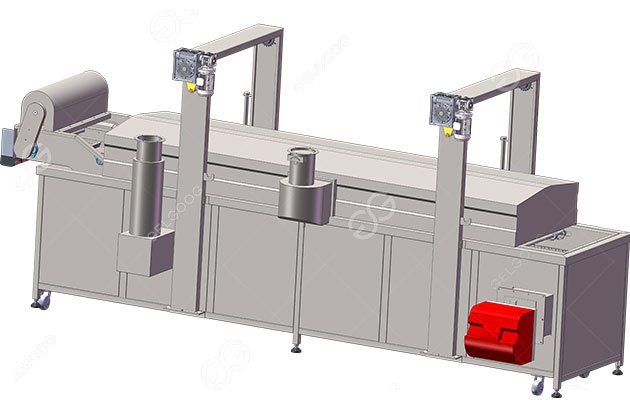

- Description: Continuous frying system machine is a fully automatic machine with low energy consumption, simple operation,high efficiency, and is deeply favored by food processing companies.

Continuous Sweet Potato Chips Frying System Machine

This continuous frying system machine is composed of a lifting system, a product conveying system, an automatic slag discharge system, an automatic heating system, an oil circulation system, an electric control system, and a smoke exhaust system. In the process of sweet potato chips processing machine, the oil temperature can be accurately controlled to keep the food at an appropriate temperature and the taste quality of the food can be improved.

Working Structure Of Continuous Frying System Machine

①Automatic discharging: The fried food can be directly conveyed to the next operation process through the mesh belt. The high degree of automation reduces the labor intensity of the workers and ensures the uniformity of the frying time.

②Automatic temperature control: The machine can set the temperature according to different foods. After setting the temperature, it can realize automatic temperature control during the frying process, thus ensuring the quality of fried foods.

③Automatic filtration: The oil-water separation frying process can automatically filter the residues generated during the frying process into the lower water, ensuring the cleanliness of the oil surface and improving the oil utilization rate.

④Automatic lifting system: the upper cover and mesh belt can be lifted and lowered for easy cleaning

Features Of Sweet Potato Chips Processing Machine

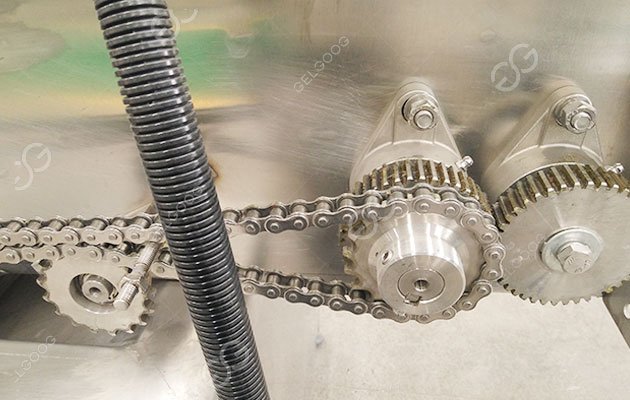

1. The mesh belt transmission adopts frequency conversion and stepless speed regulation.

2. Use natural gas, electricity, and coal as heating energy.

3. The whole continuous frying system machine adopts food grade 304 stainless steel material.

4. The unique double mesh belt design prevents the product from floating during the frying process.

5. Adopt high-efficiency heat conduction device, high energy utilization rate.

6. To ensure the health and safety of food, most of the parts in contact with the food of this fryer are made of stainless steel, which meets the standard for food production.

7. It can fry many kinds of food at the same time and ensure the color, fragrance and taste of the food.

8. Fried food has high efficiency, energy saving and environmental protection.

Continuous Frying System Machine Applications

The multi-function frying machine is widely used in fried food processing enterprises, and is suitable for the mass production of fried foods such as meat, aquatic products, vegetables, pasta, snack foods, prepared foods, nuts, potatoes, etc. Low investment and high degree of automation. Favored by food companies.

Working Structure Of Continuous Frying System Machine

①Automatic discharging: The fried food can be directly conveyed to the next operation process through the mesh belt. The high degree of automation reduces the labor intensity of the workers and ensures the uniformity of the frying time.

②Automatic temperature control: The machine can set the temperature according to different foods. After setting the temperature, it can realize automatic temperature control during the frying process, thus ensuring the quality of fried foods.

③Automatic filtration: The oil-water separation frying process can automatically filter the residues generated during the frying process into the lower water, ensuring the cleanliness of the oil surface and improving the oil utilization rate.

④Automatic lifting system: the upper cover and mesh belt can be lifted and lowered for easy cleaning

Features Of Sweet Potato Chips Processing Machine

1. The mesh belt transmission adopts frequency conversion and stepless speed regulation.

2. Use natural gas, electricity, and coal as heating energy.

3. The whole continuous frying system machine adopts food grade 304 stainless steel material.

4. The unique double mesh belt design prevents the product from floating during the frying process.

5. Adopt high-efficiency heat conduction device, high energy utilization rate.

6. To ensure the health and safety of food, most of the parts in contact with the food of this fryer are made of stainless steel, which meets the standard for food production.

7. It can fry many kinds of food at the same time and ensure the color, fragrance and taste of the food.

8. Fried food has high efficiency, energy saving and environmental protection.

Continuous Frying System Machine Applications

The multi-function frying machine is widely used in fried food processing enterprises, and is suitable for the mass production of fried foods such as meat, aquatic products, vegetables, pasta, snack foods, prepared foods, nuts, potatoes, etc. Low investment and high degree of automation. Favored by food companies.

| Model |

Beld width (mm) |

oil pump power (kw) |

lifting power (kw) |

heating power |

Dimension (mm) |

| LZG3500A | 800 | 1.5 | 0.55 | 20Wkcal | 3700*1900*2400 |

| LZG5000A | 800 | 1.5 | 0.55*2 | 30Wkcal | 5200*1900*2400 |

| LZG6500A | 800 | 1.5 | 0.75*2 | 20Wkcal*2 | 6700*1900*2400 |

| LZG8000A | 800 | 2.2 | 0.75*2 | 30Wkcal*2 | 8200*1900*2400 |

| LZE3500A | 800 | 1.5 | 0.55 | 90KW | 3700*1600*2200 |

| LZE5000A | 800 | 1.5 | 0.55*2 | 120kw | 5200*1600*2200 |

| LZE6500A | 800 | 1.5 | 0.75*2 | 190kw | 6700*1600*2200 |

| LZE8000A | 800 | 2.2 | 0.75*2 | 255kw |

8200*1600*2200 |