What Is The Process In Making Potato Chips?

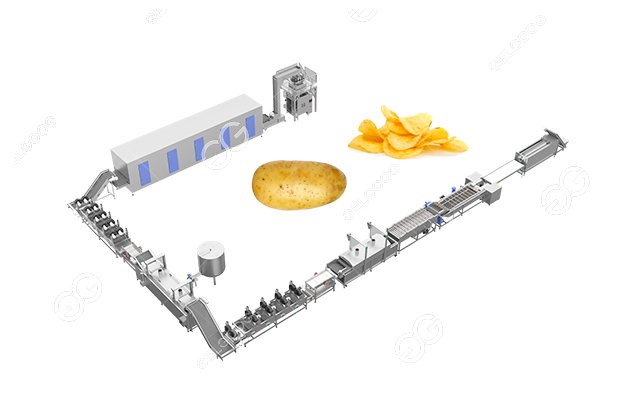

Potato chips, a beloved snack enjoyed by millions around the world, undergo a fascinating and intricate process before reaching store shelves. The journey from raw potatoes to crispy, flavorful chips involves a combination of technology, precision, and a deep understanding of the science of food processing. In this article, we'll explore what is the process in making potato chips.

Potato selection and sorting:

The process begins with the careful selection of high-quality potatoes. Varieties with low sugar and high starch content are preferred for chip production. Potatoes are then thoroughly washed and sorted to eliminate any defects or foreign materials.

Peeling and slicing:

After sorting, the potatoes are peeled to remove the skin. The peeled potatoes are then sliced into thin, uniform rounds. Precision is crucial in this step to ensure consistent thickness, which contributes to the overall quality and texture of the final product.

Pre-treatment:

The sliced potatoes undergo pre-treatment to remove excess starch and sugars. This step is essential for preventing discoloration and achieving the desired texture during the frying process. Common pre-treatment methods include blanching, washing, and sometimes even applying chemicals to preserve the color.

Drying:

The pre-treated slices are dried to remove excess moisture. This is a critical step, as residual moisture can cause the chips to be soggy rather than crispy during frying. High-speed centrifuges or hot air dryers are often employed for efficient moisture removal.

Frying:

The dried potato slices are then fried at high temperatures. This step gives the chips their signature crispy texture. The choice of oil and frying duration greatly influences the flavor and quality of the final product. Continuous monitoring and control of temperature are crucial to achieving consistency.

Seasoning:

After frying, the chips are seasoned with various flavorings. Common seasonings include salt, pepper, cheese, barbecue, and a variety of other proprietary blends. The seasoning process is carefully controlled to ensure an even distribution of flavor across all the chips.

Quality control:

Throughout the entire production process, quality control measures are implemented. This includes monitoring the size, thickness, color, and taste of the chips. Any chips that do not meet the specified standards are removed from the production line.

Packaging:

Once the chips have passed quality control, they are ready for packaging. Modern factories use automated packaging systems to weigh and fill bags with the precise amount of chips. Packaging materials are chosen to maintain the freshness and crispiness of the chips.

Distribution:

The packaged potato chips are then ready for distribution to retailers. The chips are stored and transported under controlled conditions to ensure they reach consumers in optimal condition.

The production of potato chips in a factory is a complex and highly controlled process that combines technological innovation with a deep understanding of the science of food. From the careful selection of potatoes to the precise control of frying temperatures, each step plays a crucial role in creating the crispy, flavorful snack that has become a global favorite. If you want to start the potato chips business, and need the potato chips production line, contact us.